Model No.: CWP

Brand: CWJX

Packaging: Plywood case or others per customer's request

Productivity: variable

Transportation: Ocean,Land

Place of Origin: Henan, China (Mainland)

Supply Ability: 15 sets of 20 days

Certificate: CE ISO SGS

Port: Qingdao,Shanghai,Shenzhen

Payment Type: L/C,T/T

Incoterm: FOB

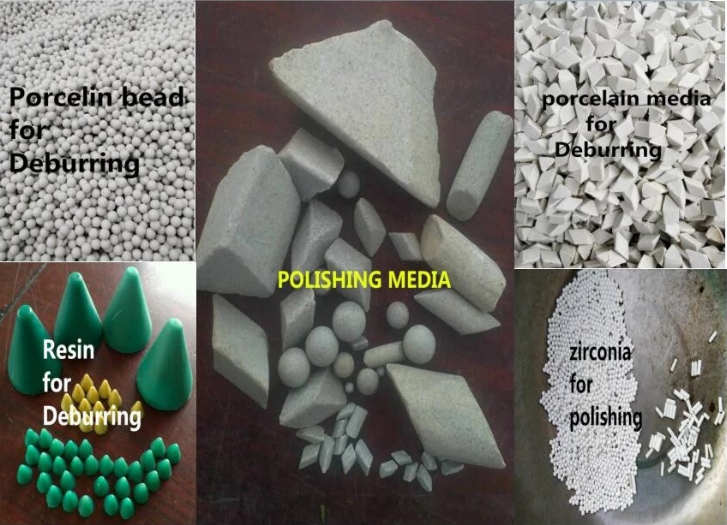

The Polishing Machine is a power tool consisting of basic components such as a base, a throwing disc, a polishing fabric, a polishing cover and a cover. The key to the operation of the polisher is to try to get the maximum polishing rate in order to remove the damage layer from the polishing as quickly as possible. At the same time, the polishing damage layer will not affect the final observed tissue, ie, it will not cause false tissue. The former requires the use of coarser abrasives to ensure a larger polishing rate to remove the polished damage layer, but the polished damage layer is also deeper; the latter requires the use of the finest material to make the polished damage layer shallower, but polished The rate is low.

Application

1. You can check our products on Alibaba.com before you sell. If you have any questions, please feel free to contact us.

2. We provide detailed video teaching installation during sales.

3. We have a one-year warranty after the sale.

Product Categories : Sieving Machine > Polishing Machine