Model No.: CWYS

Brand: Chenwei

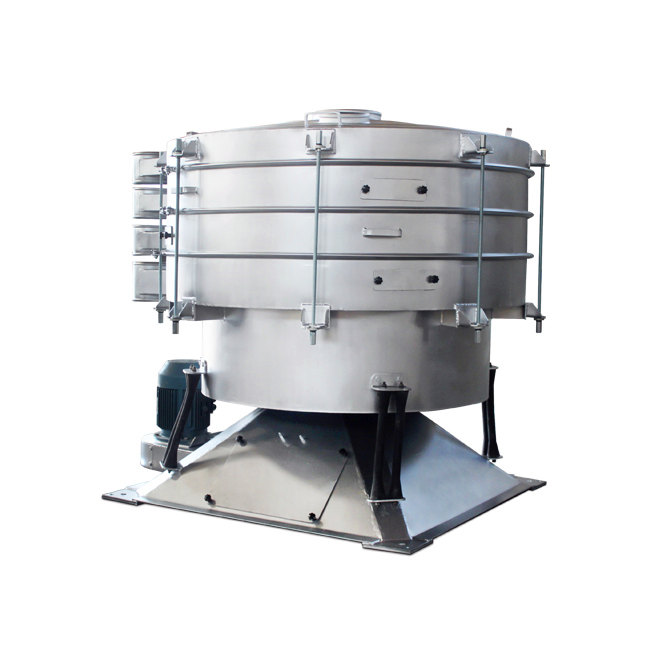

Type: Circular

Function: Screening\separation\sorting\sieving

Transmission Structure: Eccentric Vibrating Screen

Usage: Lightweight Fine Shaker

Works: Rotary Vane Shaker

Object: Food Processing

Shaft Number: Double

Running Track: Oval Sieve

Supporting Device: Rubber Spring

Warranty: 1 Year

Customized: Customized

Condition: New

After-sales Service Provided: Engineers Available To Service Machinery Overseas

Installation: Engineer Guide

Material: Stainless Steel/ Carbon Steel

Frequency: 220-280r/min

Noise Level: <75dB

Sieving Precision: 98%

Layers: 1 - 4 Layers

Sieve Mesh: 5 - 600 Mesh

Capacity: 10Kg-10Tons/hour

Packaging: Wooden box

Productivity: As the different model

Transportation: Ocean

Place of Origin: Henan, China

Supply Ability: 20 sets/month

Certificate: CE, ISO, SGS, ISO9001

HS Code: 8479820090

Port: Qingdao,Shanghai,Tianjin

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW

1)CWYS series tumbler screen machine is a kind of inertial equipment with mature technology and classical application.

Its new design Philosophy and unique structure making it the closest manual screen machine. The Tumbler Sieve machine have bright application prospects for its perfect screening effect. From the aspect of its trajectory, it is a non-linear inertial Vibrating screen. The Tumbler sieve machine is particularly used to classify small materials and fine powder according to its unique structure and working principle. It is not only apply to dry sieving, but also wet sieving. It is widely used in mine, building material, metallurgy, foundry, abrasive material, chemical, light industry, medical, food and other industry.

2)Its screen and frame are made by different materials and designed by different. Its whole sealing structure prevents materiel dust moving out, so no worry about air pollution. On the other hand,it is very easy to add drying, cooling, de dusting, cleaning and other supporting facilities as part of the Tumbler screen.

Because of the motion trajectory of the griddle box, the Tumbler screen machine is also called compound circle screen. The vibration force produced by the drive system is a kind of inertia force which is circling the dead axle and changing regularly. Intrinsically, it is a kind of centrifugal force given by the eccentricity mass circling around the dead axle. The sieve is usually installed horizontally or with tiny angle(0°-5°). The principle is:when you start the machine, the vibrating part ---the screen box takes circling motion under the influence of the vibrating force.

The screen box drive the sieve to take circling motion periodicity,so the material on screen surface take bounce motion, meanwhile, the material less than the aperture drop to the next deck,and the oversize are discharged by the outlet.Finally ,the screening work is completed. From the aspect of its structure and working principle, the exciter can in two ways according to the motion of the material, . As a result ,we'd better make a choice between throughput and efficiency according to our practical demand.

| Model | Mesh area(m2) | Screen slope | Granularity (mm) | Frequency (r/min) | Amplitude (mm) | Power (kw) |

| CWYS-600 | 0.28 | 0-10 | <=100 | 220-280 | 20-70 | 0.75 |

| CWYS-1000 | 0.66 | 1.5 | ||||

| CWYS-1200 | 0.98 | 2.2 | ||||

| CWYS-1500 | 1.67 | 3.0 | ||||

| CWYS-1800 | 2.37 | 4.0 | ||||

| CWYS-2000 | 2.89 | 4.0 | ||||

| CWYS-2600 | 5.3 | 5.5 |

1)Chemical industry: resin, pigment, cosmetic, coatings, Chinese medicine powder.

2)Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce.

3)Metallurgy, Mine industry: aluminum powered, copper powder, ore alloy powder, welding rod powder.

4)Medicinal industry: all kinds of medicine.

5)Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon.

Q:What factors I need to get a quotation?

A: Material bulk density, mesh size(length & angle for conveying series) & ideal capacity for proper type, granularity distribution is recommended. product material requirement (carbon steel Q235A, stainless steel SUS304 or SUS316,etc.) Voltage & Frequency(Hz) is also needed for a precise quotation.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipment are the most durable type in the industry, this is also the feature of the label impression of CWJX for most of our customers at home or abroad. With our experienced quality control team, we are trying to offer most of our customers the product with best quality. However, we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the warranty time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Q: How could I trust your promise?

A: Firstly, you may check the assessment on our website certified by the appraisal agency Bureau Veritas;secondly, we attend at least 4 to 6 international industry exhibitions held in China annually, like the Food Ingredients China, China International Battery Fair, CPhI, ICSE BioPh China, ICIF China, etc. We usually met our customers there for negotiation;Thirdly, company inspection always available, if you have any representative or you would like to come to our site, we offer free shuttle from Zhengzhou airport to our company, welcome your visit.

Christine Chan

Web: www.xxcwjx.com / www.cwmachinery.net

Office: +86 373 3511260

Fax: +86 373 3511601

Mobile: +86 13462298161

Whatsapp: +86 13462298161

Facebook&Messenger ID: Christine Chan

QQ: 3503103458

WeChat: 13462298161

Product Categories : Sieving Machine > Tumbler Sieve