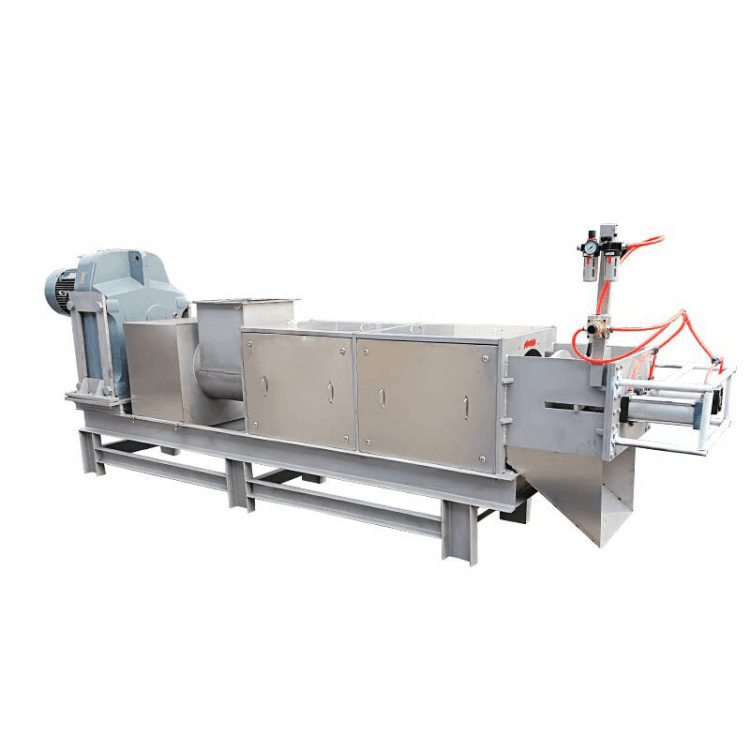

Model No.: CW-SLA CW-SLB

Brand: CWJX

Condition: New

Warranty: 1 Year

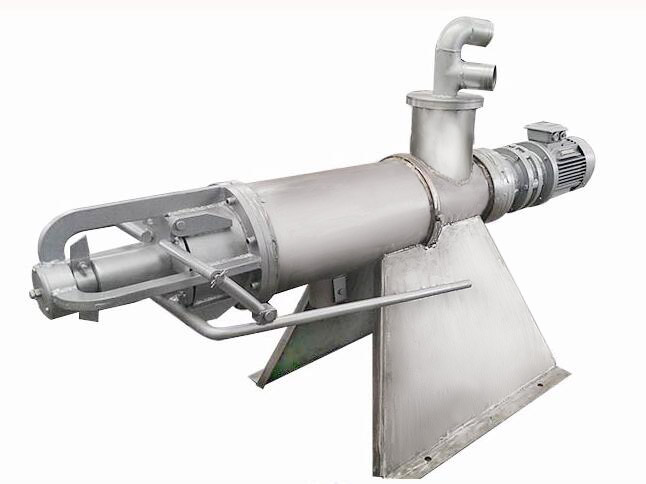

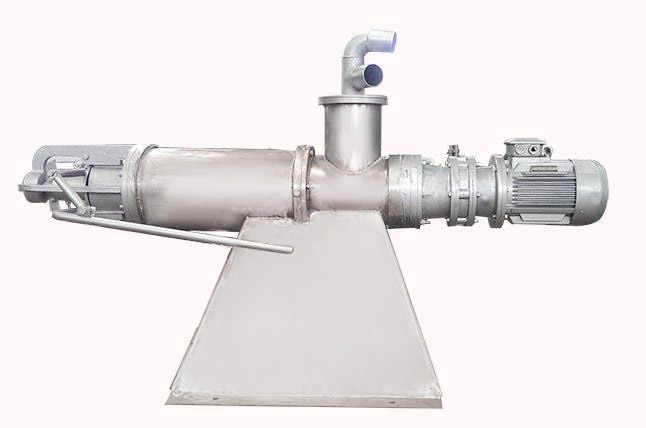

Type: Chenwei- Solid Liquid Separator

Material: Carbon Steel/ Stainless Steel 304

Voltage: 220V/280V/415V/450V

Power(W): 4-5.5KW

Handling Capacity: 7-20m3/h

Usage: Liquid Material

Function: Separater

Packaging: Wooden packing

Productivity: According to the order

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 30 sets/month

Certificate: BV CE ISO SGS

Port: Qingdao,Shanghai,Shenzhen

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

Product Application

In many solutions for wastewater pollution, the use of solid-liquid separators to separate pig manure is a better option with less investment and significant economic benefits.

Advantages of spiral extrusion Solid-liquid Separator: high degree of automation, slow running speed, simple operation, convenient maintenance, high daily output, low power consumption, suitable for continuous operation. Most of its parts are made of stainless steel and have a small machine size, making it ideal for large farms. It has greatly improved the handling and benefits of livestock and poultry waste. The machine can also be customized to different industries and users.

Product Parameters

| Commodity | Mode | Motor power | Reduction box | Speed(r/s) | Voltage | Capacity(m3/h) | ||

| | CWY-280 | 5.5kw | 5-43 | 33.7 | 380V | Cow dung | Pig manure | Poultrydung |

| CWY-280 | 5.5kw | 5-43 | 33.7 | 380V | 4-6 | 5-12 | 2-4 | |

| Water pump | | 3KW | | 1450 | 380 | | | |

Advantage Characteristics

Practicality: The separation speed of the series of slag liquid is fast, the moisture content of the separated slag is between 50-60%, the slag amount and water content can be adjusted, and it can be applied to different feeds. It is easy to transport, and its solid content is suitable as a raw material for fish feed and organic fertilizer.

Advanced: This series of machines has strong decontamination ability, no clogging and easy cleaning. The treated solid waste water, chemical oxygen demand, total oxygen consumption, nitrogen and phosphorus removal rate can be between 70-95%.

Durability: The frame, screen frame, screen and etc. of this series are made of stainless steel and anti-corrosion treatment, which is corrosion resistant, high strength and long service life.

Economical: The series is highly automated, consumes less power and has a lower price. Easy to operate, just press the start and stop button to operate.

Xinxiang Chenwei Machinery Manufacturing Co., Ltd. is a professional manufacturer integrating screening, conveying, lifting and pulverizing equipment, integrating scientific research, production and sales. Chenwei Machinery is located in Xinxiang High-tech Development Zone. The company is based on strong technical force, advanced production equipment and strict management system. With the tenet of value-added enterprise reputation, innovative technology and good service, after 30 years of development, Become a well-known company in the industry. Chenwei Machinery mainly produces Vibrating screen, Vibrating Screen, Linear Vibrating Screen, Ultrasonic Vibrating Screen, test screen, air flow screen, filter screen, inspection screen, mine screen, tap screen, vibration motor, conveyor, feeder, etc. Various materials and equipment, widely used in food, chemical, resin, pharmaceutical, ceramics, metal powder mining and metallurgy, paper and other industries.

Exhibition

1)We provide 12months quality warranty to make sure your machine well runs consistently.

2)Professional engineer design the production line for you.

3)Recommend suitable equipment according to your special demand.

4)Common problem can be solved through web in 24 hours,complex problem can be reacted immediately in 24 hours and solved as soon as possible.

FAQ

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry. With our experienced quality control team, we are trying to offer most of our customers the product with bset quality. However, we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the gurantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Product Categories : Solid-liquid Separator